What is critical defects, major defects and minor defects?

Defects found in inspection are classified into three categories: critical defects, major defects and minor defects:

1) Critical defects:

Critical defects could result in hazardous or unsafe conditions for individuals using or maintaining the product, as well as defects contravening legal regulations.

2) Major defects:

Major defects may affect the duration of product or reduce the ability to use the item (poor functioning, item incomplete or broken, etc.) or give it a flawed appearance which may affect the product value.

3) Minor defects:

Minor defects are unlikely to reduce the use of the product but nevertheless may influence the visual aspect.

Aimbest uses the MILITARY STANDARD 105E (MIL-STD-105E),tables, which are recognized standards by every industrial company.

This American standard now has equivalents in all national and international standardization organizations (ANSI/ASQC Z1.4, ISO 2859, NF06-022, BS 6001, DIN 40080).

This standard is a proven method to accept or reject a production lot by inspecting a randomly selected number of products.

This method is called 'AQL'(Acceptable Quality Level):

As a quality control company in China, Aimbest uses the Acceptable Quality Level (AQL) to establish a maximum allowable error rate or variation from the standard. Acceptance testing will cease immediately if the failure rate of the product being tested exceeds the minimum Acceptable Quality Level.

NB: It is important to note that Acceptance Sampling cannot provide 100% perfect products. The only way of achieving this is to produce 100% perfect products.

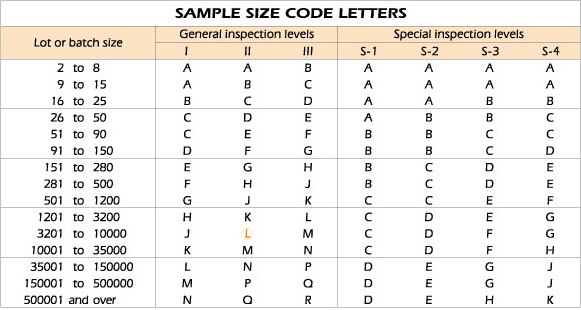

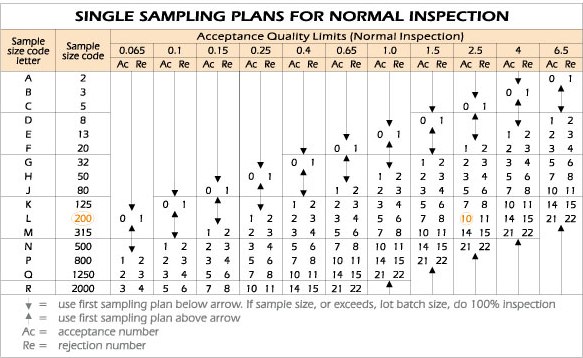

MIL STD 105E TABLE

Practically, Aimbest Quality Standards use the MIL-STD-105E tables that are summarized below:

What can I find out from the AQL tables?

Suggestion on AQL Levels

|

Classification |

High Valued Products |

Low-medium Valued Products |

|

Critical Defects |

0 |

0 |

|

Major Defects |

AQL1.0/1.5 |

AQL2.5 |

|

Minor Defects |

AQL2.5/4.0 |

AQL4.0 |

Understanding AQL

How do I determine the right sample size and acceptance number?

As an example, in an inspection of a 3,500 unit lot, with an Acceptable Quality Level of II, Table A indicates that sample size code letter should be "L" . Table B indicates that the sampling size of "L" should be 200 units. For an AQL of 2.5, the corresponding acceptance number is 10.

What does this mean in concrete terms?

If the number of defective units is higher than 10, the lot should be rejected. It also means that, if the lot passes inspection, there is a 95% chance that less than 5% (10 defects in this example) of the entire inspected lot will be defective.

What should I do with defective or discarded lots?

Defective items found as part of 100% inspection can be discarded, repaired or replaced. You may opt to buy the discarded lot at a discount for resale at a lower price.